Blog

An educational blog on clothing branding, product packaging and sustainable innovation, providing you with both informative articles and videos, to hopefully inspire the designs for your next fashion collection.

6 min read time

|

Feb 5, 2025

As we reflect on Veganuary, it's now time to take action. Your brand has a golden opportunity to...

The importance of retail security tags

Is Adidas sustainable?

Is Nike sustainable? Focusing on a brighter future

What are care labels and can you brand them?

Sustainability

The importance of retail security tags

3 min read time

|

Jan 29, 2025

Online fashion has changed the way the world shops. As this global trend grows, customers...

Read more

Sustainability

Is Adidas sustainable?

10 min read time

|

Jan 17, 2025

Known for its iconic three stripes, Adidas is a global giant in sportswear and fashion. But is it...

Read more

Sustainability

Is Nike sustainable? Focusing on a brighter future

10 min read time

|

Jan 17, 2025

Nike is an instantly recognisable name worldwide, whether for its iconic trainers, performance...

Read more

Labels

What are care labels and can you brand them?

8 min read time

|

Jan 17, 2025

Care labels do more than just provide washing instructions. They're a key touchpoint between your...

Read more

Garment Branding

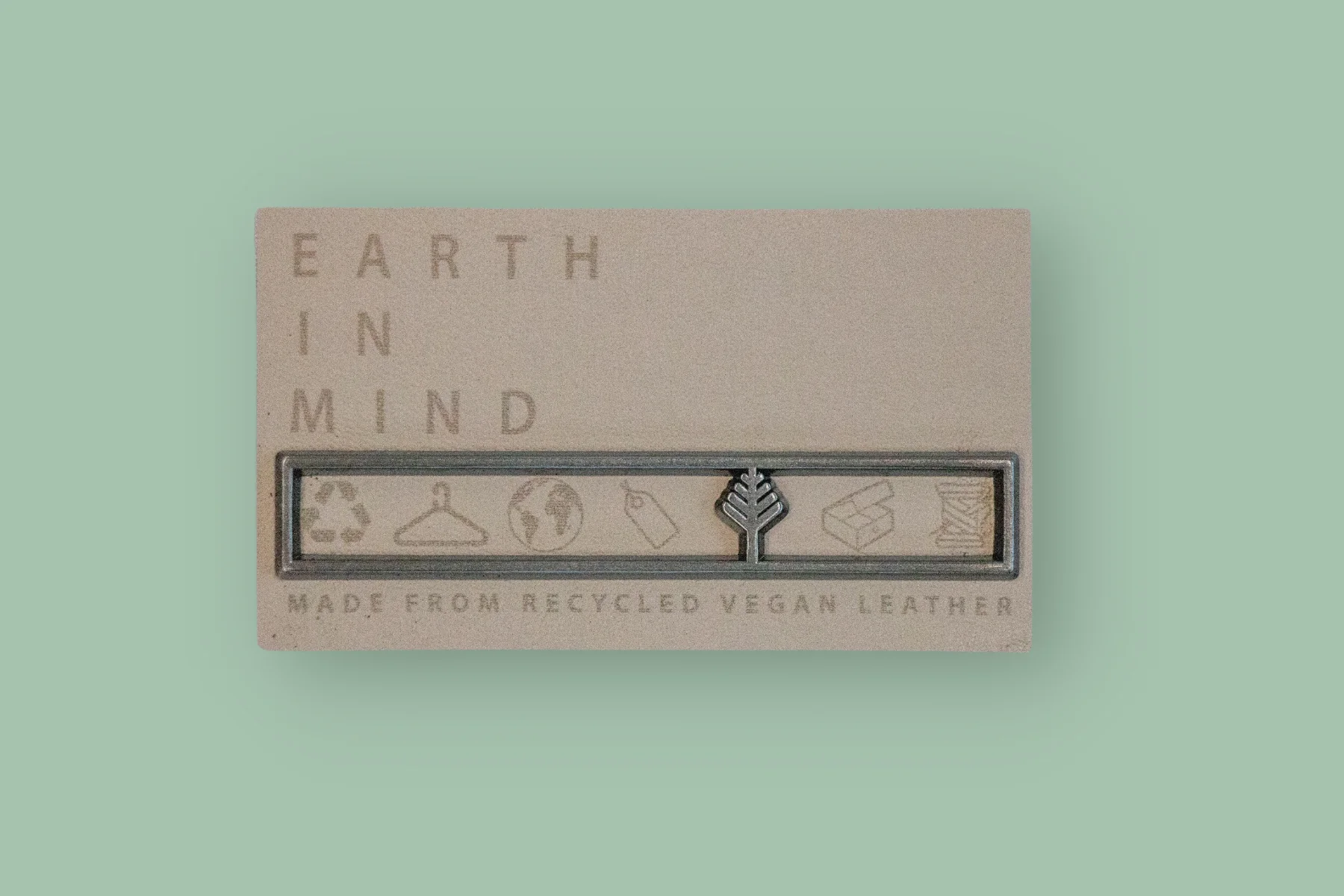

The overlooked importance of retail hang tags

9 min read time

|

Dec 16, 2024

Retail hang tags are more than just an accessory to indicate product costs. They are an often...

Read more

Sustainability

Greenwashing in fashion: How to spot it

6 min read time

|

Nov 25, 2024

More brands are working towards sustainability and minimising their carbon footprint. While others...

Read more

Packaging

What’s the True Impact of Packaging on Retailers and Consumers?

4 min read time

|

Nov 13, 2024

We all want to achieve the instantly recognisable status of Gucci and Tiffany & Co. The majority of...

Read more

quality

Printed labels vs Woven labels: Which are better?

5 min read time

|

Nov 11, 2024

Labels can say a lot about a brand. Not just in terms of the colour or the design but the texture...

Read more

Sustainability

The sustainable fashion glossary

7 min read time

|

Nov 11, 2024

Ethical and sustainable fashion terminology isn’t always as easy as it seems. With such a big focus...

Read more

Compliance

EU Deforestation Regulation (EUDR)

5 min read time

|

Oct 24, 2024

Traceability and compliance: EUDR supports global action to tackle climate.

Read more

Sportswear

Is Girlfriend Collective sustainable? Sustainable activewear with a difference

5 min read time

|

Sep 12, 2024

Describing itself as the Earth's number one fan, Girlfriend Collective is one of the most...

Read more

How do retro football shirts support sustainable fashion?

6 min read time

|

Sep 10, 2024

Whether you're a football fan or not, it's hard to ignore the explosion in popularity of retro...

Read more

Sustainability

Zero waste fashion: Is it achievable?

8 min read time

|

Sep 2, 2024

It's zero waste week, so what better way to mark the occasion than investigating whether zero waste...

Read more

Sustainability

Is Adanola sustainable?

3 min read time

|

Aug 15, 2024

Instagram-born brand Adanola has become one of the most iconic sportswear brands. Famous for its...

Read more

Sustainability

7 sustainable cycling clothing brands

4 min read time

|

Aug 5, 2024

Getting outdoors on your bike allows you to experience the wonders of the planet. Whether cycling...

Read more

Sustainability

Paris Olympics 2024: Sustainability in the Olympics

4 min read time

|

Jul 29, 2024

Summer holds some of the biggest sporting events in the annual calendar, and the Paris Olympics...

Read more

Sustainability

10 top brands for sustainable golf clothing

6 min read time

|

Jul 22, 2024

The spotlight is turning on the sportswear industry to become more sustainable, and golf apparel...

Read more

Sustainability

Wimbledon sustainability: We take a look

4 min read time

|

Jul 8, 2024

Sustainability is at the top of the agenda for businesses in every sector, with sports no...

Read more

Packaging

How flat-pack packaging can be your brand’s secret weapon

4 min read time

|

Jun 24, 2024

When people hear ‘flat-pack packaging’, they envision plain yet efficient and convenient boxes....

Read more

Sustainability

Is Zara sustainable? An overview of the fast fashion giant

5 min read time

|

Jun 17, 2024

It's one of the biggest names on the high street, with more than 10.9 million customers to prove...

Read more

Sustainability

Is IKEA sustainable? Exploring the homeware giant’s practices

4 min read time

|

Jun 3, 2024

You’ll struggle to find anyone who doesn’t recognise this Scandinavian furniture and homewares...

Read more

Sustainability

Is M&S sustainable?

4 min read time

|

May 21, 2024

Considered an iconic British institution, Marks & Spencer — or as it's more commonly known, M&S —...

Read more

Eco-Friendly

What does it mean to be GOTS-certified in fashion?

5 min read time

|

May 20, 2024

In today’s eco-conscious world, it’s no longer enough to say that your products are sustainable....

Read more

Fashion

The North Face clothing brand: Is it sustainable?

6 min read time

|

Apr 15, 2024

The North Face clothing brand is an instantly recognisable household name that's been a favourite...

Read more

Sustainability

PANGAIA sustainability: Exploring the brand's credentials

4 min read time

|

Apr 4, 2024

PANGAIA's popularity has grown exponentially thanks to its fresh approach to apparel in a market...

Read more

recycled

What are the pros and cons of recycled polyester?

5 min read time

|

Mar 27, 2024

About 49% of the world’s clothing is made of polyester, and forecasts show this to nearly double by...

Read more

Branding

Your Product Packaging Terms and Glossary

7 min read time

|

Mar 18, 2024

Packaging is a crucial component in building a brand’s image and identity. Often, it can be the...

Read more

Sustainability

What is social sustainability and why is it on every company’s agenda?

3 min read time

|

Mar 5, 2024

Sustainability is a broad term that covers all kinds of areas, including society. But what is...

Read more

Sustainability

The evolution of consumer sustainability trends

4 min read time

|

Mar 4, 2024

Consumer attitudes towards sustainability have evolved as we’ve moved through the decades. From an...

Read more

recycled

Sustainability focus: Recycled leather

4 min read time

|

Feb 26, 2024

As conscious consumerism continues to grow, sustainable materials are taking centre stage in the...

Read more

Fashion

Is Coach a luxury brand? Diversifying for the future consumer

5 min read time

|

Feb 5, 2024

It’s a brand that has been a staple in many wardrobes since it began in the 1940s. Today, it’s a...

Read more

Fashion

Sustainable development goals: How fashion plays its part

5 min read time

|

Jan 22, 2024

As the global climate crisis accelerates at an alarming rate, governing bodies and global...

Read more

Sustainability

15+ sustainable fashion facts you need to know

4 min read time

|

Jan 15, 2024

As the climate crisis intensifies and consumers become increasingly eco-aware, the fashion...

Read more

Packaging

What are bio-based materials for packaging and trims?

3 min read time

|

Dec 13, 2023

Materials are constantly evolving to plug gaps and offer eco-friendly alternatives to options we...

Read more

Branding

How to create a brand story with tailored trims

3 min read time

|

Dec 11, 2023

Creating a cohesive brand image is a task many businesses must face to stay competitive.

Read more

Packaging

Get ahead for next year with sustainable Christmas packaging

2 min read time

|

Dec 4, 2023

Amidst the celebrations of Christmas, there’s the growing and often overlooked concern about...

Read more

Sustainability

TALA sportswear: Sustainable sportswear from top to toe

5 min read time

|

Nov 27, 2023

Since its inception in May 2019, TALA has been making waves with its commitment to creating...

Read more

Sustainability

Is sustainability in sportswear possible?

5 min read time

|

Nov 20, 2023

Sustainability is a topic that no industry can escape. Consumers are becoming more aware,...

Read more

Sustainability

What is Oceans of Plastic and how does our ocean collection support?

3 min read time

|

Nov 13, 2023

Ocean plastic pollution is at its height. With over 80% of all marine pollution from plastic waste,...

Read more

Eco-Friendly

What is sustainable fashion and how can your brand make the change?

6 min read time

|

Sep 18, 2023

Sustainable fashion is no longer a buzzword but a necessity in the fashion industry. As the amount...

Read more

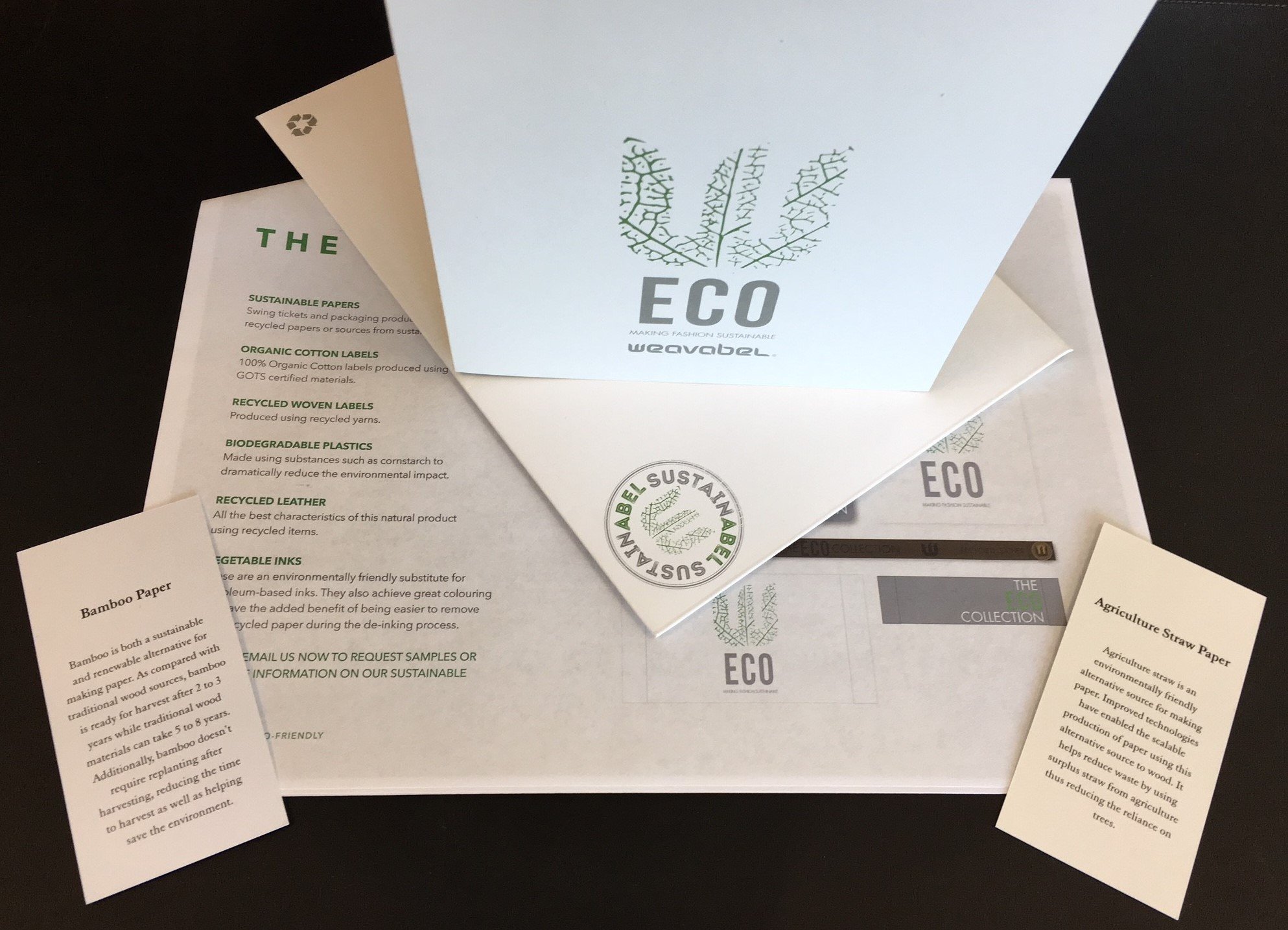

Garment Branding

7 reasons why you should work with Weavabel, a sustainable packaging supplier

6 min read time

|

Sep 4, 2023

We get it — looking for a new sustainable packaging supplier can be challenging. How can you be...

Read more

Sustainability

Our sustainability certifications: What they are and why we have them

5 min read time

|

Aug 14, 2023

Sustainability certifications are the difference between saying something is sustainable and...

Read more

Sustainability

Sustainable fashion materials: Do they exist?

6 min read time

|

Aug 7, 2023

Up to 100 billion garments are produced every year. Even more shocking is that 92 million tonnes of...

Read more

Fashion

8 sustainable streetwear brands to watch

5 min read time

|

Aug 1, 2023

We’re all familiar with the impact the fashion industry has on the environment and the streetwear...

Read more

Branding

How we develop custom trims and packaging that enhance your product

4 min read time

|

Jun 12, 2023

Considering 50% of shoppers will recommend your product if it comes in branded packaging, we’d say...

Read more

Packaging Ideas

How Packaging and Supply Chain Unlock Sustainability

6 min read time

|

Feb 13, 2023

Governments across the globe are signing legislation promising to battle climate change, reduce...

Read more

Eco-Friendly

The Eco-Friendly Alternatives to Poly Bags

5 min read time

|

Feb 6, 2023

As sustainability goes under the microscope, all eyes are on the fashion, eCommerce and retail...

Read more

Packaging Ideas

7 Eco-Friendly Packaging Ideas for 2023

5 min read time

|

Feb 3, 2023

As we enter another year, sustainability is more important than ever. However, for many fashion,...

Read more

Fashion

Is Patagonia a ‘Good’ Brand? The Fight for Feel-Good Consumerism

10 min read time

|

Jan 30, 2023

When the words ‘sustainable fashion’ are mentioned, more often than not, Patagonia is one of the...

Read more

Luxury

How to Market Luxury Products — 8 Secrets for Success

7 min read time

|

Dec 12, 2022

As the abundance of luxury products increases and maintaining customer loyalty becomes a constant...

Read more

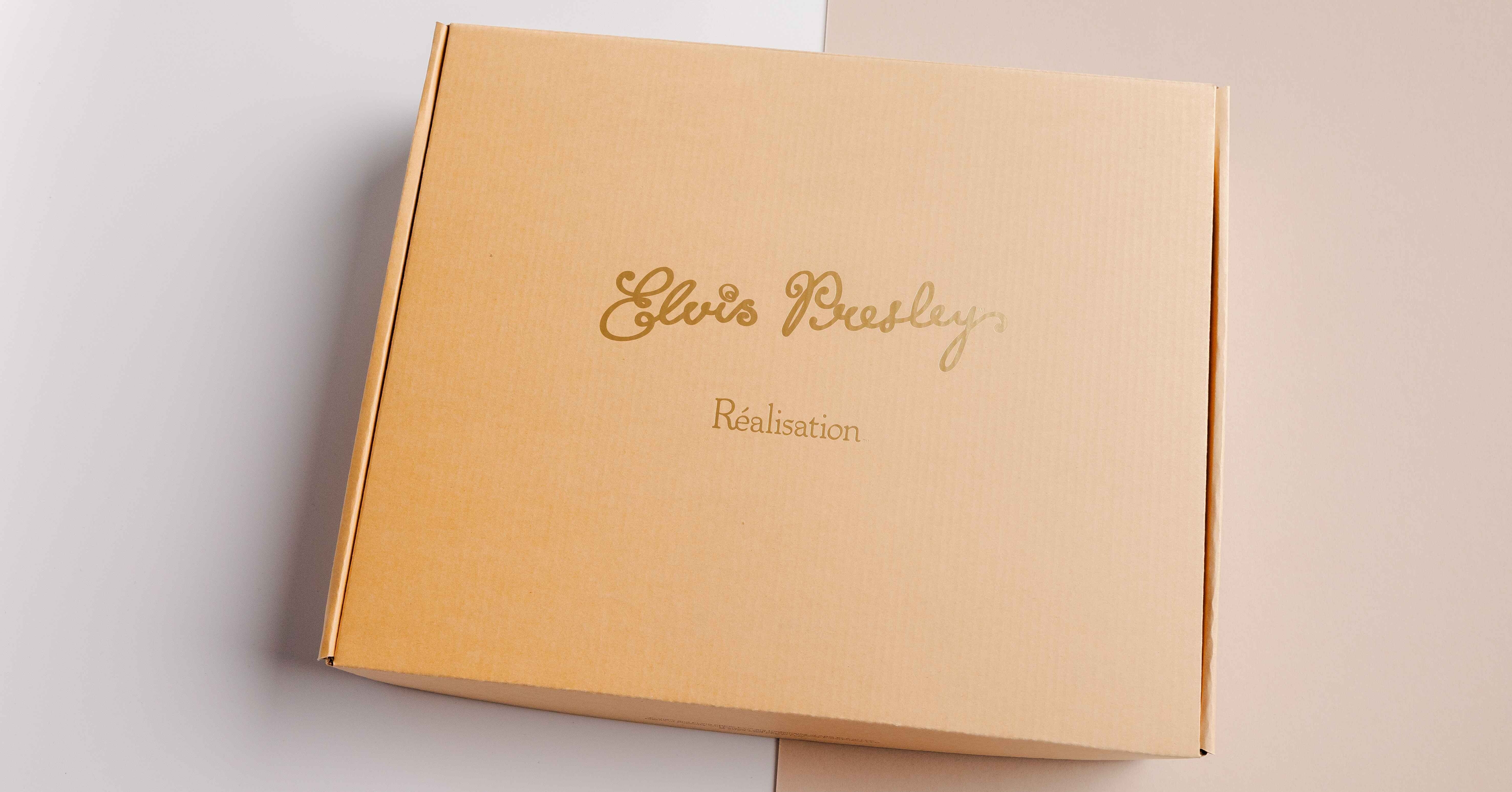

Packaging

How to Launch a Luxury Brand and Cut Through the Noise

4 min read time

|

Dec 2, 2022

In today's overcrowded marketplace, launching a brand with impact can be challenging, particularly...

Read more

Luxury

Is Karl Lagerfeld Paris a luxury brand?

5 min read time

|

Nov 15, 2022

Karl Lagerfeld is one of the most recognisable names in the fashion sphere. Iconic for heading up...

Read more

Fashion

Is Barbour a luxury brand?

5 min read time

|

Nov 1, 2022

For over a century, Barbour has been an instantly recognisable British brand that’s got a luxury...

Read more

Eco-Friendly

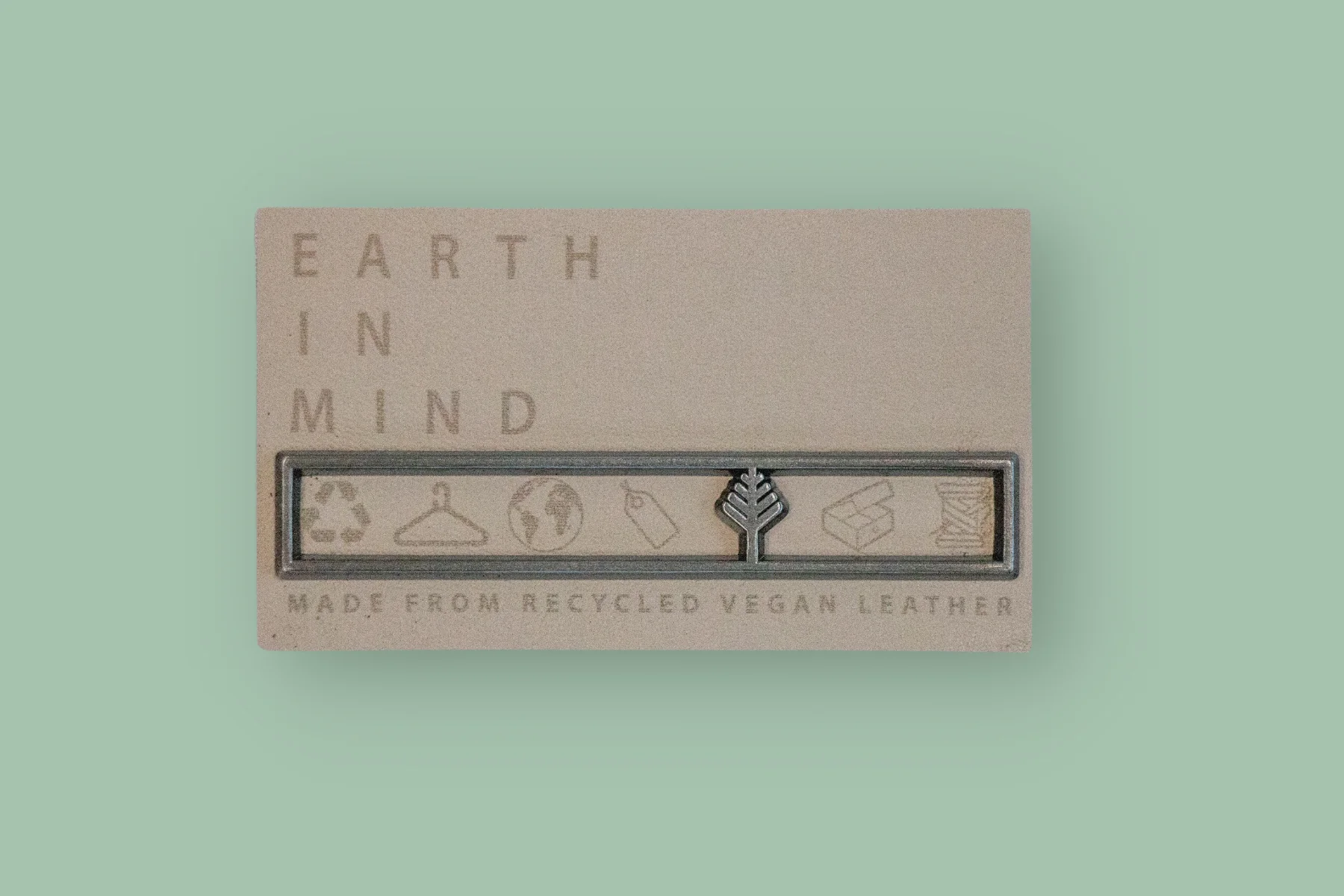

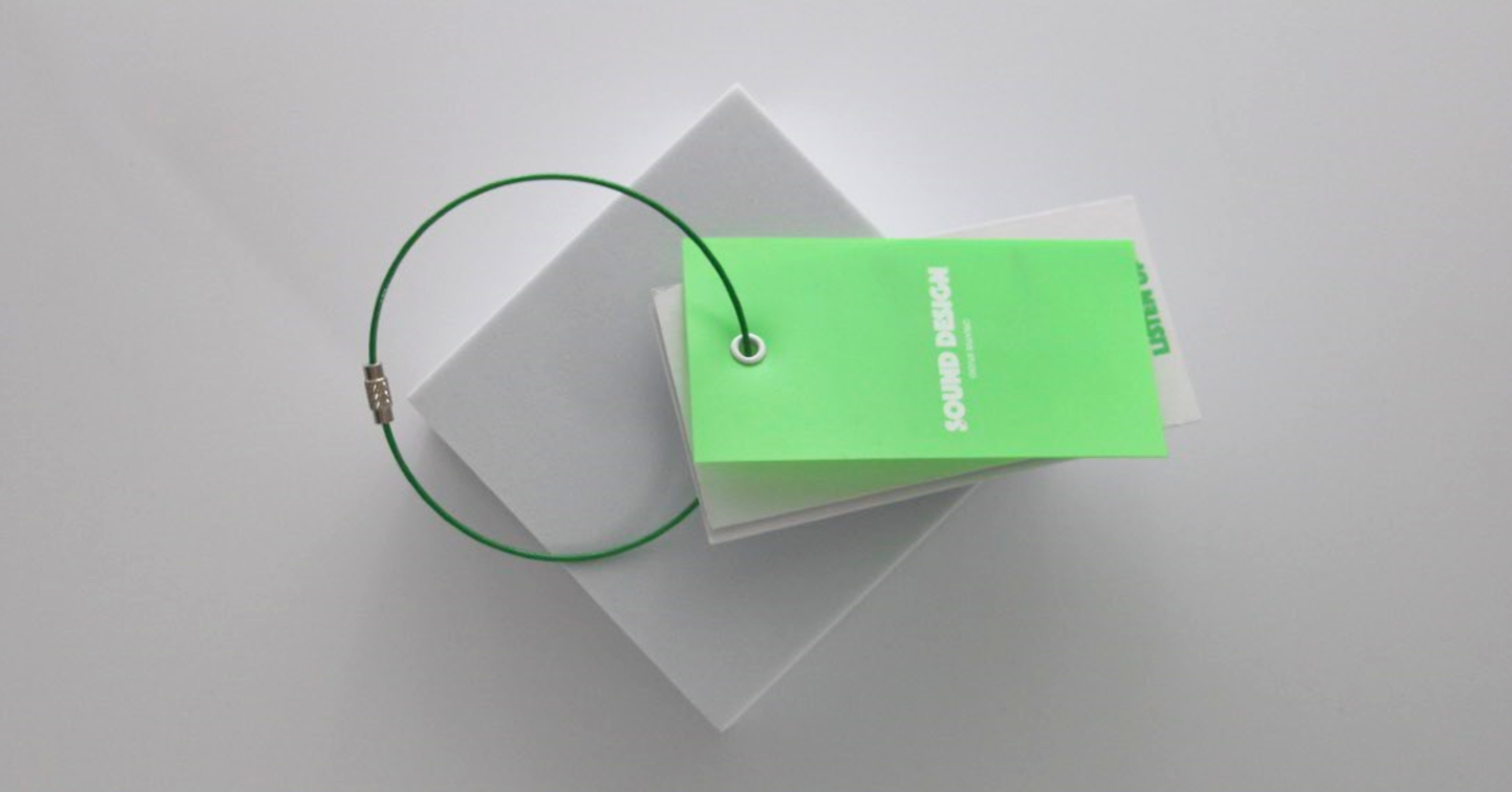

The Earth in Mind Collection: Our most eco-friendly collection to date

2 min read time

|

Oct 12, 2022

The global fashion industry creates 10% of all greenhouse gas emissions, with a truckload of...

Read more

Fashion

Is Lacoste a luxury brand?

5 min read time

|

Oct 10, 2022

Lacoste is an instantly recognisable brand name. Steeped in history, this iconic French brand has...

Read more

Fashion

Why ‘Luxury’ Doesn’t Mean the Same Thing to Modern Consumers

4 min read time

|

Oct 3, 2022

Luxury is a word we’re all familiar with, yet it means many different things to different people....

Read more

Packaging Ideas

E-commerce Packaging Trends That Can Increase Online Orders

5 min read time

|

Sep 5, 2022

In 2021, e-commerce revenue in the UK reached £129 billion, up 15% from 2020, with 64% of online...

Read more

Packaging Ideas

15 innovations in packaging materials we're excited about

8 min read time

|

Aug 1, 2022

As the world looks more towards sustainability, brands are constantly trying to innovate packaging....

Read more

Packaging Ideas

The Best Luxury Brand Packaging in Fashion, Sportswear and Home

6 min read time

|

Jul 26, 2022

A critical part of the luxury product experience is its packaging. For your customer, there’s...

Read more

Sustainability

11 brands leading the way in sportswear sustainability

7 min read time

|

Jun 27, 2022

Looking to explore sustainability and find inspiration from the brands leading the way? Then you’ve...

Read more

Sustainability

Top 6 Materials for Sustainable Sportswear

5 min read time

|

Jun 6, 2022

Cheap, manufactured, unsustainable fabrics have long been the focus of the sportswear industry,...

Read more

Sustainability

What Are the Success Factors for Sustainable Luxury?

5 min read time

|

May 27, 2022

According to research, around 66% of shoppers said they consider sustainability when purchasing a...

Read more

Sustainability

8 Sustainable Luxury Brands To Look Out For

6 min read time

|

May 3, 2022

The fashion industry is notorious for its negative impact on the environment. But this doesn’t mean...

Read more

Sustainability

Sustainability in the Homeware Industry: Tackling Fast Homeware

7 min read time

|

Apr 26, 2022

Homeware is an industry that has boomed in recent years, projected to be worth £13.8 billion by 2022

Read more

Sustainability

11 Sustainable Homeware Brands

6 min read time

|

Apr 18, 2022

Sustainability is no longer a buzzword but a primary concern for brands and consumers alike. As the...

Read more

Sustainability

All You Need to Know About Circular Fashion

6 min read time

|

Mar 18, 2022

Circular fashion. It’s the concept transforming the fashion industry and consumer attitudes....

Read more

Sustainability

7 Sustainable Habits to Encourage Circular Fashion

5 min read time

|

Mar 10, 2022

As governments, industries, brands and consumers become more environmentally aware, the need for...

Read more

Sustainability

9 Brands That Are Embracing Fashion Upcycling

6 min read time

|

Mar 1, 2022

Sustainability. We’ve all heard about it and we all know how important it is for improving the...

Read more

designs

The Role of Circular Design in Reducing Environmental Impact

5 min read time

|

Feb 9, 2022

Materials, trims, colours, silhouettes — designers hold a great deal of power in the design...

Read more

Sustainability

What Are the Drivers and Barriers to a Circular Economy?

8 min read time

|

Feb 7, 2022

The circular movement is gaining traction, with more and more fashion businesses committed to...

Read more

Sustainability

How Can Fashion Brands Transition From a Linear to a Circular Economy?

8 min read time

|

Feb 1, 2022

The fashion industry as we know it needs to change — but that’s much easier said than done. Worth...

Read more

Sustainability

How Is the Circular Fibres Initiative Impacting Sustainability in Fashion?

7 min read time

|

Jan 24, 2022

It’s estimated that more than half of fast fashion produced is disposed of in under a year, with ...

Read more

Sustainability

The Circular Fashion Economy — A Sustainable Model or an Attempt to Greenwash?

6 min read time

|

Jan 17, 2022

Circular fashion is the term on the fashion industry’s lips. Touted as the path for change in the...

Read more

Packaging Ideas

Managing Your Supply Chain in the Garment Industry

10 min read time

|

Jan 7, 2022

A well-managed supply chain can significantly reduce a company’s operating costs and improve...

Read more

Sustainability

12 Sustainable Fashion Trends to Look Out for in 2022

10 min read time

|

Jan 3, 2022

No longer just a buzzword in the fashion industry, sustainability is here to stay. As new...

Read more

Packaging Ideas

How to Choose the Right Fashion Label Supplier

4 min read time

|

Jan 3, 2022

The right fashion label supplier should use advanced technology to meet your exact brand...

Read more

Sustainability

Why is Being GRS Certified Becoming More Important?

4 min read time

|

Jul 23, 2021

With the introduction of the Plastic Packaging Tax coming in 2022, many businesses are scrambling...

Read more

Packaging Ideas

8 New Creative and Eco-Friendly Clothing Trim and Packaging Ideas

5 min read time

|

May 14, 2021

Clothing trims and packaging are two key considerations for premium brands, especially those in...

Read more

Sustainability

Fast Fashion and Sustainability: Will the Two Ever Get Along?

7 min read time

|

Apr 27, 2021

Fast fashion still has a long way to go when it comes to sustainability. In fact, the nature of...

Read more

Eco-Friendly

Eco-Friendly Garments and How They Can Make Fashion Sustainable

6 min read time

|

Apr 27, 2021

Fashion as an industry is one of the biggest carbon emitters, producing 8-10% of the world’s global...

Read more

Packaging Ideas

How to Create a Sustainable Unboxing Experience for Your Brand

9 min read time

|

Feb 12, 2021

You’ve probably seen them before - videos where celebrities or everyday customers show off their...

Read more

Packaging Ideas

10 Sustainable Packaging Trends On Our Radar

9 min read time

|

Jan 22, 2021

What’s one of the most appealing factors for consumers when buying products? Sustainability. Your...

Read more

Packaging Ideas

Ethical Packaging and Premium Branding - Can You Have Both?

3 min read time

|

Jan 8, 2021

Today, your brand can achieve both ethical packaging and premium branding without compromising....

Read more

The Most Iconic Bespoke Packaging Designs In the Fashion Industry

4 min read time

|

Oct 29, 2020

Textures, fonts, colours and compositions on a product can really change how we feel and experience...

Read more

Eco-Friendly

What are the Benefits of Eco-Friendly Packaging?

7 min read time

|

Oct 12, 2020

Packaging is everywhere; in your shopping trolley, your cupboards, your deliveries and so much...

Read more

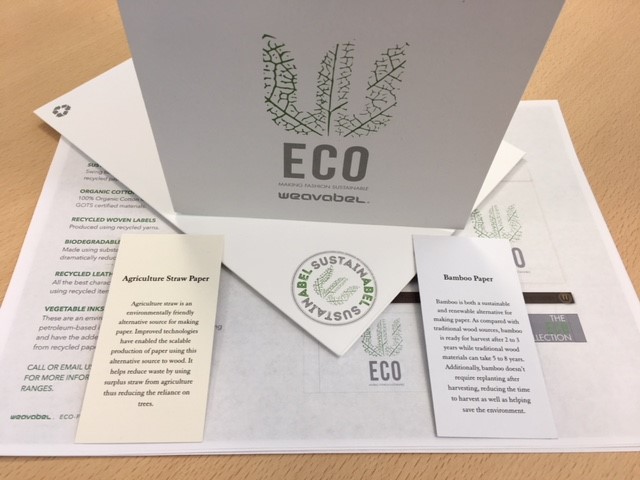

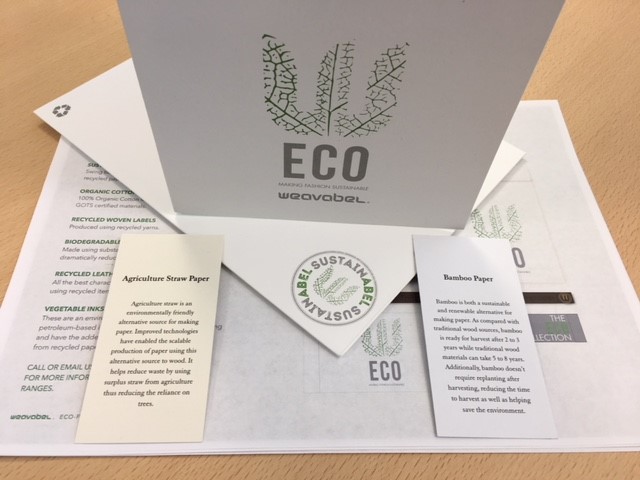

Sustainable Branded Packaging Solutions

4 min read time

|

Sep 27, 2020

First Impressions Count. Packaging is a powerful way of communicating your brand to the wider...

Read more

Circularity vs. Sustainability – What is the difference?

5 min read time

|

Sep 20, 2020

You might have heard of circularity and sustainability. Both focus on making industries more...

Read more

Eco-Friendly

6 of the best eco-friendly luxury packaging to inspire you

5 min read time

|

Aug 30, 2020

In the recent strides towards sustainability, there’s an increasing need for brands to change their...

Read more

Fashion

From Concept To Reality: Everything You Need To Know About Fashion Production

5 min read time

|

Jan 20, 2020

The fashion production process isn’t straight forward, especially if you’re a new fashion company...

Read more

Eco-Friendly

Eco-Friendly Manufacturing and Packaging: What Brands Are Doing Right Now

4 min read time

|

Jan 7, 2020

A big part of the current waste crisis is a direct result of packaging - with the fashion...

Read more

Packaging

The Different Types of Packaging Boxes That Can Transform Your Brand

3 min read time

|

Dec 30, 2019

Packaging isn’t just a practical and necessary part of your product, it’s also an extension of your...

Read more

Packaging

Keep It Simple - How to Make Packaging More Sustainable for Your Brand

3 min read time

|

Dec 25, 2019

Consumers are now increasingly reliant on eCommerce to fulfil their retail needs. However, they're...

Read more

Packaging

The Cost of Sustainable Packaging — Is It More Expensive?

6 min read time

|

Dec 23, 2019

UK households created approximately 2.5 million metric tonnes of plastic waste in 2021 and only ...

Read more

Packaging Ideas

Hidden Benefits of Foil Stamping And How They Aid Packaging Solutions

2 min read time

|

Dec 16, 2019

Foil stamping is a metallic reflective finish that has the potential to transform conventionally...

Read more

uv coating

What is UV Coating and Does My Packaging Need it?

4 min read time

|

Dec 13, 2019

Ultraviolet (UV) coating is a transparent liquid compound that's applied to a surface and then...

Read more

Packaging

How to Make Dieline Packaging

4 min read time

|

Dec 9, 2019

In the packaging and printing industry, the term “dieline” refers to the template needed to ensure...

Read more

Packaging Ideas

What Is Flexographic Printing and What are Its Pros and Cons?

3 min read time

|

Dec 2, 2019

Flexography (often abbreviated to flexo) is a printing process which utilises a flexible relief...

Read more

Packaging

How to Choose a Luxury Retail Packaging Specialist

4 min read time

|

Nov 25, 2019

Packaging design is a crucial component in building your brand’s image and identity. The majority...

Read more

Packaging

How to Make Your eCommerce Packaging Solutions Eco-Friendly

5 min read time

|

Nov 15, 2019

There was a time when consumers begrudged separating their recyclables from rubbish and when online...

Read more

Packaging Ideas

Embossing vs. Debossing: Which Has More Impact For Your Packaging?

4 min read time

|

Nov 11, 2019

It’s a well-known packaging debate - what should you incorporate in your design? Embossing and...

Read more

Packaging Ideas

9 Innovative Flat Box Packaging Examples

6 min read time

|

Nov 8, 2019

Bespoke flat box packaging is user-friendly, attention-grabbing and aesthetically-pleasing. And...

Read more

Packaging

Matte vs Gloss Lamination: Which Is Better for Packaging?

4 min read time

|

Nov 4, 2019

How do you want your consumers to feel when they hold your packaging in their hands for the first...

Read more

Packaging Ideas

5 Stunning Eco Kraft Packaging Concepts and Real-Life Examples

4 min read time

|

Oct 31, 2019

Sustainable packaging is becoming a high priority for both brands and consumers. With an increasing...

Read more

Sustainability

4 Types of Sustainable Trims (and Innovative Examples to Inspire You)

4 min read time

|

Oct 28, 2019

Although trims are just a small part of manufacturing as a whole, we should all strive to be more...

Read more

Packaging

Which Brands Have Adopted Sustainable Retail Packaging?

4 min read time

|

Oct 25, 2019

Whether you’re selling clothing, food, tech gadgets or cosmetics, as a retail company, you need to...

Read more

Packaging

What Strides Are Fashion Brands Making Towards Sustainable Clothing Packaging?

5 min read time

|

Oct 18, 2019

Wasteful and harmful packaging solutions are going out of fashion. As landfills are bursting at the...

Read more

Eco-Friendly

The Hidden Benefits of Vegetable Inks and Why You Should Be Using Them

3 min read time

|

Sep 30, 2019

The fashion world’s approach to sustainability is changing. New production methods are being used....

Read more

Eco-Friendly

The 7 Biggest Advantages of Biodegradable Plastics and How You Can Use Them

6 min read time

|

Sep 23, 2019

The fashion industry uses a lot of traditional plastic. Microplastics have been found in Arctic snow

Read more

Sustainability

Sustainable Fashion Examples: How to Take Inspiration From World-Leading Brands

5 min read time

|

Sep 20, 2019

Designer. Luxury. Sustainability. Three words that might seem like they’re miles apart, but fashion...

Read more

Sustainability

Organic Cotton: 6 Wonderful Examples of Brands That Do It Right

4 min read time

|

Sep 14, 2019

Labels aren’t just placed on garments to tick a box. Eye-catching labels made from high-quality...

Read more

Sustainability

How Can Fashion be Sustainable? How Far Off Are We?

5 min read time

|

Sep 11, 2019

The world of fashion revolves around the latest trends to meet consumer demand. Although, the only...

Read more

Eco-Friendly

Recycled Leather: What Is It and Which Brands Are Using It?

4 min read time

|

Sep 9, 2019

The impact of the fashion industry is causing increasing devastation to the environment. As a...

Read more

Eco-Friendly

The Benefits of Being Eco-Friendly (And How Other Major Brands Are Doing It)

5 min read time

|

Sep 6, 2019

It’s no secret that the fashion industry has and continues to have a disastrous impact on the...

Read more

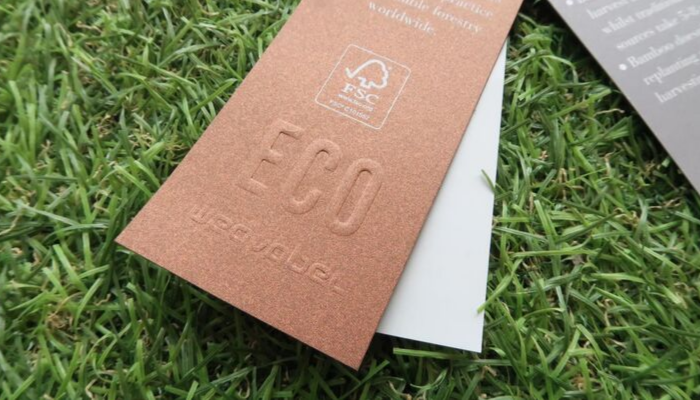

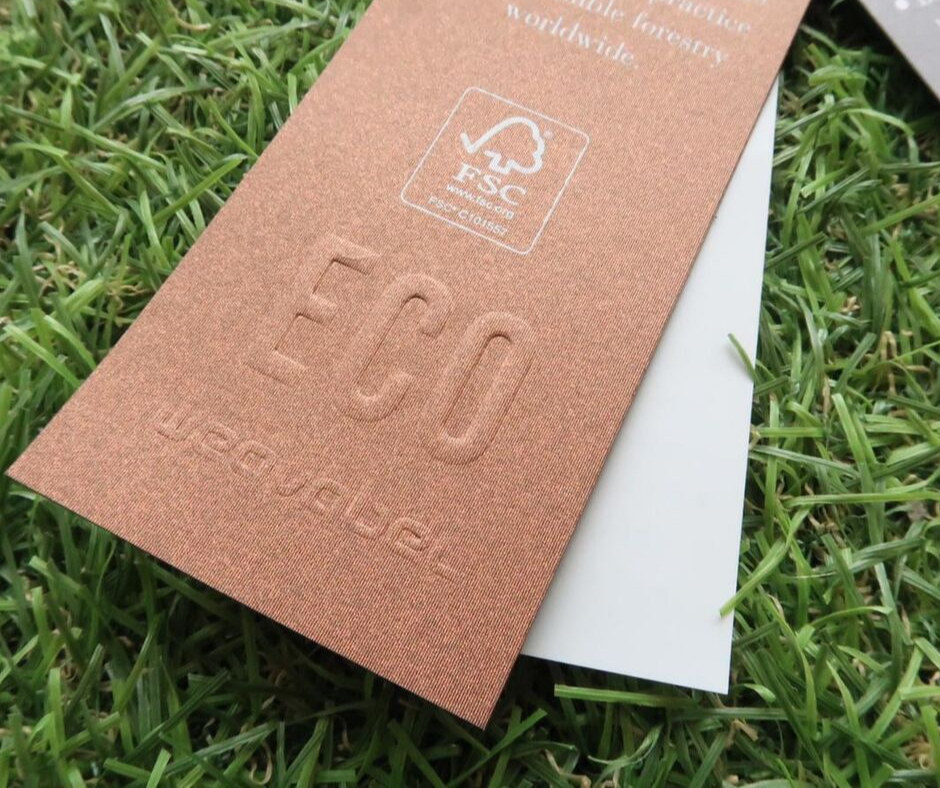

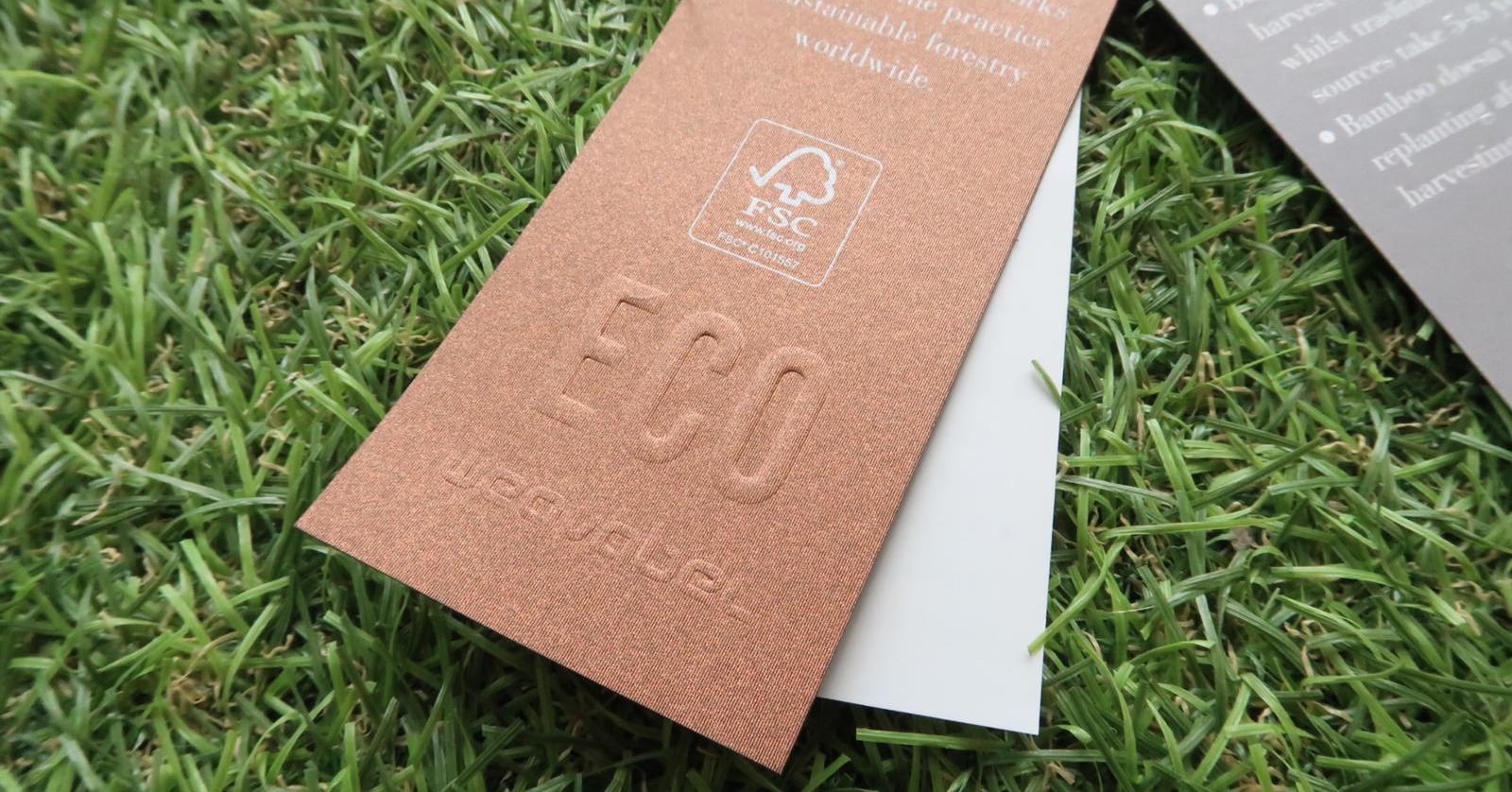

Sustainability

Why Should I Use FSC Certified Suppliers?

5 min read time

|

Aug 26, 2019

FSC certifications are familiar to most of us now. They're seen as the global gold standard for...

Read more

Eco-Friendly

5 of the Best Eco-Friendly Fashion Brands (and Why They’re Winning the Ethical Race)

4 min read time

|

Aug 23, 2019

Buying less but better is a mantra that we should all try to stick by. Especially when you consider...

Read more

Packaging Ideas

9 Types of Biodegradable Packaging to Better Your Brand Footprint

7 min read time

|

Aug 19, 2019

According to National Geographic, there are over five trillion pieces of plastic debris in the...

Read more

Sustainability

Sustainable Practices in Retail: How to Go Green and Do it Well

6 min read time

|

Aug 16, 2019

Sustainability has always been somewhat of a niche approach in retail. Although, more and more...

Read more

Packaging Ideas

Corn Starch Packaging: It's the New Polystyrene

3 min read time

|

Aug 9, 2019

Today’s environmentally conscious consumer wants to know how their products are sourced and how far...

Read more

Sustainability

How Does Sustainability Impact Brand Value?

4 min read time

|

Aug 5, 2019

When it comes to sustainability and corporate social responsibility, many brands adopt the mindset...

Read more

Packaging Ideas

Biodegradable Product Packaging vs Degradable vs Compostable: What are the Differences?

4 min read time

|

Jul 29, 2019

Whether it’s Patagonia’s pledge to support grassroots environmental groups or Puma’s switch to...

Read more

Sustainability

10 Brands That Have Embraced Eco-Friendly Manufacturing and Packaging Solutions

7 min read time

|

Jul 22, 2019

By 2050, our oceans are expected to contain more plastic than fish. Harrowing statistics like this...

Read more

Global Supply

CMT vs FPP: Which is the Best method for Your Brand?

3 min read time

|

Jun 28, 2019

Choosing the right manufacturer to collaborate with can be a difficult task as you want to make...

Read more

Global Supply

What? Why? How? All About Full Package Production

4 min read time

|

Jun 21, 2019

When looking for a factory for your upcoming projects, you’ll need to do a lot of research when it...

Read more

Branding

9 Innovative Branding Trims and Why They Had Such an Impact

7 min read time

|

Jun 17, 2019

At the heart of any brand is a first-class product that customers instantly want to get their hands...

Read more

Garment Branding

10 Types of Swing Tag Printing Techniques and Why It’s Vital to Choose the Right One

5 min read time

|

Jun 13, 2019

Swing tickets and hang tags are subtle yet innovative branding tools that can provide vital product...

Read more

Garment Branding

What Branded Trims Add to Your Athleisure Range

3 min read time

|

Jun 11, 2019

Athleisure is no longer new and niche. Its rise in popularity has been meteoric with...

Read more

Garment Branding

Why You Should Try Luxury Swing Tags (Even If You're Not a High End Brand)

3 min read time

|

Jun 6, 2019

Even if you’re not a high fashion brand, adding a luxury swing tag to your garments can be...

Read more

Labels

Embroidered Labels: How Can They Improve a Garment’s Design?

3 min read time

|

May 13, 2019

Woven labels, sometimes known as embroidered labels and badges, represent a traditional look that...

Read more

Branding

What Role Does Brand Packaging Play in Building a Company's Identity?

4 min read time

|

May 3, 2019

Packaging design is a crucial component in building a brand’s image and identity. The majority of...

Read more

Branding

4 Ways to Boost Your Clothing Brand Identity

4 min read time

|

Apr 22, 2019

The importance of your brand identity can’t be understated – especially in the forever evolving...

Read more

manufacturing

CMT Clothing: The Pros and Cons

4 min read time

|

Apr 19, 2019

Deciding on your clothing manufacturer can be tricky in the initial stages of production and...

Read more

Garment Branding

4 Ways Clothing Badges Make Big Statements

3 min read time

|

Apr 16, 2019

Although your branding might not be as recognisable as the simplistic and strong Barbour or the...

Read more

Labels

Leather Patch - A Product Manager's Best Way to Stay Ahead

3 min read time

|

Apr 14, 2019

Leather patches are stylish, sophisticated and unique. The high-quality material never goes out of...

Read more

Labels

7 Garments and Accessories That Go Perfectly with Heat Transfer Badges

3 min read time

|

Apr 9, 2019

Heat transfer badges are the perfect finishing touch and are always very popular in the...

Read more

Labels

Pin Badges: All About This Underrated Accessory

4 min read time

|

Apr 4, 2019

Embellishing bags and jackets with pin badges are back in style. This popular trend that bedazzled...

Read more

Branding

Top 6 Types of Garment Trims You Need to Know About

4 min read time

|

Apr 1, 2019

Garment trims are accessories added to clothing items, enhancing brand image and adding value to...

Read more

Branding

How Swing Tags Help Boost Brand Awareness More Than You Think

2 min read time

|

Apr 1, 2019

If you’re looking to boost brand recognition and identity while also providing key product...

Read more

Branding

Can a Nominated Supplier Save You Money?

3 min read time

|

Oct 20, 2017

Should you put all your eggs in one basket and go with a nominated supplier? Or should you divide...

Read more

Labels

Know Your Label Sizes

2 min read time

|

Oct 19, 2017

As the prices in the fashion industry keep crunching, it's our guess you as buyers keep coming...

Read more

Packaging Ideas

5 Unique Mail Order Packaging Examples

3 min read time

|

Jul 19, 2017

Net-A-Porter and Amazon Prime are rocking the boat with their industry-changing new mail order...

Read more

Embroidered Badges

5 Ways to apply Big Embroideries to your Garments

2 min read time

|

Jun 15, 2017

Embroidered badges and patches are all trending right now. Appliques, woven and embroidered figures...

Read more

Packaging Ideas

Insanely Creative Packaging

4 min read time

|

Apr 25, 2017

What makes buying a garment, or actually any product, special? Is it the fact that you genuinely...

Read more

Compliance

Guide to Childrenswear Compliance

3 min read time

|

Apr 5, 2017

When designing children's clothing, it is important to take into consideration the behaviour of...

Read more

Trends

The Nautical Traveller - SS18 Trend

2 min read time

|

Jan 27, 2017

The maritime aesthetic is now not only for those travelling the high seas to explore oceans and...

Read more

designs

What is good design?

5 min read time

|

Jan 18, 2017

How do we define 'good' design principles? Good design is often described as a blend of form,...

Read more

Weavabel

A Statement Detail

1 min read time

|

Jan 10, 2017

Sometimes, product detail leaves us truly amazed. Something a little cooler, a little more...

Read more

Branding

Creating a Lab of Innovation

1 min read time

|

Dec 20, 2016

It is no secret that we're fans of revolutionary concepts, exotic textures combined with vibrant...

Read more

Branding

A Guide to Successful Garment Branding

2 min read time

|

Dec 12, 2016

For a brand to survive in today's market, it has to have a relatable purpose that resonates. Now...

Read more

Garment Branding

Tomorrow is Calling - Denim PV

2 min read time

|

Nov 23, 2016

You probably know how important it is to plan for the future, to anticipate the future and to be...

Read more

Weavabel

Welcome to the Weavabel Journal

1 min read time

|

Oct 24, 2016

It’s the start of an exciting journey that we would like to share with the world!You may have...

Read more

Sign up for our newsletter

Want to keep up to date with industry developments, trends, product launches and more? Sign up to our newsletter to get the latest delivered to your inbox.